Material Of Construction

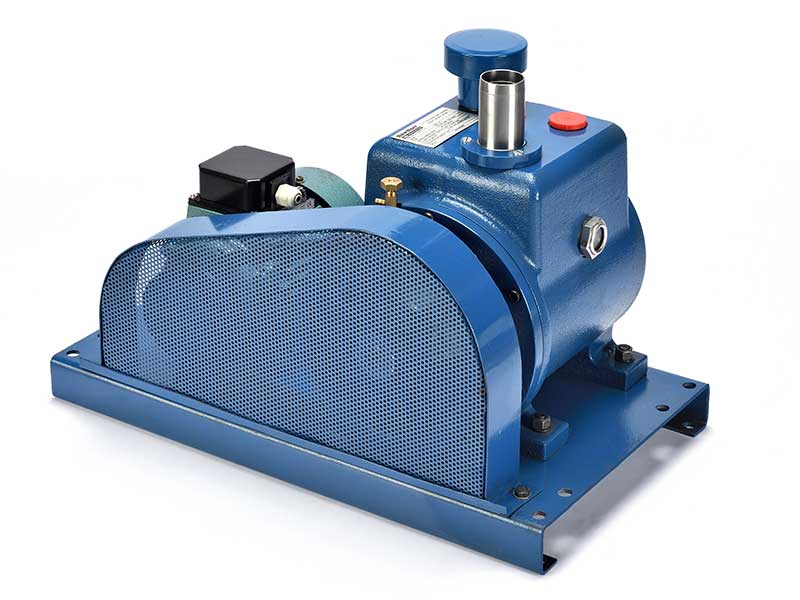

- Housing – Cast Iron

- End Plates – Cast Iron

- End covers – Cast Iron

- Rotors – Ductile Iron

- Shafts – Ductile Iron cast integrally with rotor

- Bearings- Gear End – Double row ball Free end and drive shaft –Single row ball

- Gears – Heat treated & Hardened alloy steel

- Seals – DE & NDE – Double Lip mounted on SS shaft sleeve or Slinger seal, optional-Mechanical Seal

- Out board Drive shaft Sea – Double Lip seal or Mechanical Seal

- Lubrication – Oil splash system at both DE & NDE Oil chamber’s with optional water cooling Coils inside the Oil chamber’s.

Water Injection Manifold – Fitted inside the square Flange of the Suction Port for uniform water spraying on the end to end length of the Lobes surface Area.

Water Cooled End Plates – DE & NDE – optionally offered.

Standard Construction Coating(Optional)

- Housing – Cast Iron internally coated with Zylon/PFA/PEEK/PTFE

- End Plates – cast Iron internally coated with Zylon/PFA/PEEK/PTFE

- End covers – Cast Iron

- Rotors – Ductile Iron Externally coated with Zylon/PFA/PEEK/PTFE

- Shafts – Ductile Iron cast integrally with rotor externally coated with Zylon/PFA/PEEK/PTFE

Material Of Construction – SS316 Construction (Optional)

- Housing – SS316

- End Plates – SS316

- End covers – Cast Iron

- Rotors – SS316

- Shafts – SS316

- Bearings- Gear End – Double row ball Free end and drive shaft –Single row ball

- Gears – Heat treated alloy steel, helical cut

- Seals – DE & NDE – Double Lip seals mounted on SS shaft sleeve, Drive shaft – Double Lip seal

- Lubrication – Oil splash system at both DE & NDE Oil chamber’s with water cooling Coils inside the Oil chamber.

Electro Pnumatic Booster By Pass Valve

| Pump | MVR250 | MVR400 | MVR600 | MVR900 | MVR1000 | MVR1200 | MVR2000 | MVR2500 | MVR3000 | MVR4000 |

|---|---|---|---|---|---|---|---|---|---|---|

| Model | ||||||||||

| Type | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly | Butterfly |

| Size | 1” | 1” | 1” | 2” | 2” | 3” | 3” | 3” | 3” | 3” |

| Operation | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic | Electropnumatic |

| Solenoid Supply Voltage | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz | 230V/24V,1ph,50Hz |

| Solenoid | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP | FLP/NonFLP |

By pass valve has been fitted across the pump for initial rough vacuum in the system under evacuation(ie for stripping process application etc ) or faster evacuation to sub atmospheric pressure for Mechanical Booster pump operation within Maximum Pressure Differential across pump.This will also isolate the pump if acidic vapours are evacuated from system under evacuation from atmospheric pressure. Hence no chance of erosion/corrosion in the pump as the load is handled by dry vacuum pump which is having all internal parts coated with PFA. Electrically Interlocked to Vacuum transmitter & booster pump motor to close the valve when booster starts at set sub atmospheric pressure

Booster Suction Vacuum Switch/Transmitter

| Pressure Transmitter | Vacuum Switch |

| Pressure range : 0 to -760mm of Hg abs | Pressure range : 0 to -760mm of Hg abs |

| Differential Pressure :50 mm of Hg abs | Differential Pressure :50 mm of Hg abs |

| Type–FLP/Non FLP | Type–FLP/Non FLP |

| Supply Voltage - 230V/24V,1ph,50Hz | Supply Voltage - 230V/24V,1ph,50Hz |

Booster Discharge Temperature Switch/Sensor

At discharge of booster pump,temp switch/sensor is provided to cut off the pump at excessive high discharge temp in the event of opening of any valve in system under evacuating leading to atmospheric air inrush etc.

| Temp Sensor | Temp Switch |

| Type : RTD100 | Temperature range : 0 to 150 degC. |

| Gland –FLP/Non FLP | Type–FLP/Non FLP |

| Temperature range : 0 to 150 degC. | Differential Temperature range – 50 degC |

Mechanical Booster Vacuum Pump Operation By Variable Frequency Drive (VFD)

The mechanical booster pump RPM is Varied w.r.t. the suction pressure from 1000-3000RPM by VFD.This is done through vacuum transmitter o/p signal to variable frequency drive w.r.t suction pressure. The frequency drive operation is programmed as below.

| Pressure transmitter O/P current is proportional to the Inlet pressure | Mechanical Booster Pump RPM setting wrt O/p Current of Pressure Transmitte |

Features Of Operation Of Mechanical Booster Vacuum Pump By Variable Frequency Drive

- Very fast evacuation from sub atmospheric pressure by Mechanical Booster Vacuum Pump is possible as the pump rotational speed is controlled by Electronic sensors having fastest response time.

- Mechanical Booster Vacuum pump can be safe and easily operated at a maximum speed of 2900 RPM , thus pump can be operated at full efficiency as the pump efficiency in terms of suction flow rate and compressibility is highest at high pump RPM. Thus small (reduction in) size of mechanical booster and backing rotary vacuum pump.

- Fine control of Pumping capacity to maintain the required pressure & flow in the system under evacuation to prevent carryover of vapours in to the pump or unnecessary overloading of the pump, thus eliminating the need of PID control in distillation unit and energy saving is achieved for required flow & pressure operation of the pumping unit.

- Complete Fail safe and very easy single push button vacuum pumping unit operation. Compact in size and light weight.

| Pump Model | MPB250 | MPB400 | MPB600 | MPB900 | MPB1000 | MPB1200 | MPB2000 | MPB2500 | MPB3000 | MPB4000 |

|---|---|---|---|---|---|---|---|---|---|---|

| VFD Rating(with Backing Pump) | 3HP, | 3HP | 5HP, | 7.5HP, | 7.5HP, | 7.5HP, | 10HP, | 10HP, | 15HP, | 15HP, |

| VFD Rating(with out Backing Pump) | 10HP | 12.5HP | 20HP | 25HP | 30HP | 40HP | 50HP | 60HP | 75HP | 100HP |

PLC/DCS Based Operation & Control Instrumentation For Mechanical Booster Vacuum Pump Package

- Pressure Transmitter/Switch at suction of the Booster Pump for measurement & control of Pressure, electrically interlocked to VFD

- Variable Frequency Drive for capacity & pressure control electrically interlocked to Booster Pump Electric Motor

- Temperature Sensor/switch at Discharge of the Booster Pump for measurement & control of Temperature, electrically interlocked to booster pump by pass control Valve

- Booster by pass l Valve fitted across the pump for initial rough vacuum in the system under evacuation (i.e. for stripping process application etc ) or faster evacuation to sub atmospheric pressure for Mechanical Booster pump operation within Maximum Pressure Differential across pump.

All the Instruments are skid mounted on the Mechanical Booster Pump having common base frame.

Electrical Control Panel

Type – Non Flame ProofAll Electrical Control Circuitry is placed inside the panel for sequential operation of the MVR.It consists of

- Mains Switch – Siemens/L&T or equivalent

- Booster Pump ”ON & OFF” Switches

- VFD is fitted inside the panel

- PLC is Fitted inside the panel

Control Panel is skid mounted on the common base frame of Booster Vacuum Pump with Electrical Instruments Cabling to the Electrical Motor & Instruments.

Interconnecting Piping & Common Base Frame

By pass valve with manifold at suction and is fitted across the booster vacuum pump with interconnecting piping and booster vacuum pump machine along with the Instruments and Electrical Control Panel is Skid mounted on common base frame having easy access to all the equipments for operation and maintenance.

MOC – Common Base frame & Skid – MS Piping – CS/SSTesting Of Mechanical Booster Vacuum Pump

Mechanical Booster Vacuum Pump is tested as per BS1571 Part II

| Pump Model | MVR250 | MVR400 | MVR600 | MVR900 | MVR1000 | MVR1200 | MVR2000 | MVR2500 | MVR3000 | MVR4000 |

|---|---|---|---|---|---|---|---|---|---|---|

| FAD at 60Hz at 3600RPM | 272m3/hr | 408m3/hr | 680m3/hr | 918m3/hr | 1224m3/hr | 1360m3/hr | 2040m3/hr | 2720m3/hr | 3400m3/hr | 4590m3/hr |

| FAD at 50Hz at 2880RPM | 225m3/ hr | 325m3/hr | 550m3/hr | 750m3/hr | 1000m3/hr | 1100m3/hr | 1650m3/hr | 2200m3/hr | 2750m3/hr | 3700m3/hr |

| Ultimate Vacuum | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs | 1x10-3Torr/mm of Hg abs |

| Maximum Pressure Differential across pump | 50Hz -170mbar 60Hz -120mbar | 50Hz -160mbar 60Hz -115mbar | 50Hz -160mbar 60Hz -115mbar | 50Hz -150mbar 60Hz -110mbar | 50Hz -150mbar 60Hz -115mbar | 50Hz -100mbar 60Hz -75mbar | 50Hz -90mbar 60Hz -70mbar | 50Hz -85mbar 60Hz -65mbar | 50Hz -80mbar 60Hz -60mbar | 50Hz -75mbar 60Hz -55mbar |

| Motor | 3HP,2pole | 3HP,2pole,3 | 5HP, | 7.5HP, | 7.5HP, | 7.5HP, | 10HP, | 10HP, | 15HP, | 15HP, |

| Power | ,3ph,50/6 0Hz,440V,2880/360 0RPM | ph,50/60Hz, 440V,2880/3600RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3ph,5 0/60Hz,440 V,2880/360 0RPM | 2pole,3p h,50/60H z,440V,2 880/360 0RPM |

| Maximum Continuous Operating Pressure | 50Hz-45mbar(3 3.75Torr) 60Hz-35mbar(27 Torr) | 50Hz-45mbar(33. 75Torr) 60Hz-35mbar(27Torr) | 50Hz-50mbar(37. 5Torr) 60Hz-40mbar(30Torr) | 50Hz-57mbar(44T orr) 60Hz-48mbar(37Torr) | 50Hz-57mbar(44T orr) 60Hz-48mbar(37Torr) | 50Hz-57mbar(44T orr)60Hz-48mbar(37Torr) | 50Hz-68mbar(51T orr)60Hz-58mbar(45Torr) | 50Hz-68mbar(51T orr)60Hz-58mbar(45Torr) | 50Hz-65mbar(48. 75Torr) 60Hz-55mbar(41.25Torr) | 50Hz-60mbar( 45Torr) 60Hz-50mbar(37.5Torr) |

| Minimum Backing Pump Size | 36m3/hr | 60m3/hr | 90m3/hr | 120m3/hr | 180m3/hr | 200m3/hr | 250m3/hr | 300m3/hr | 450m3/hr | 600m3/h r |

| Suction &Discharge Port Size | 2” | 2” | 2” | 4” | 4” | 6” | 6” | 6” | 8” | 10” |

| Dimensions (Bareshaft Unit) | 473.3mm( L)X228.6( W)x336.6mm(H) | 524mm(L)X228.6(W)x377.9mm(H) | 625.6mm(L) X228.6(W)x 377.9mm(H) | 703.3mm(L) X304.8(W)x 381mm(H) | 779.5mm(L) X304.8(W)x 381mm(H) | 741.4mm(L) X406.4(W)x 508mm(H) | 830.6mm(L) X406.4(W)x 508mm(H) | 906.5mm(L) X406.4(W)x 508mm(H) | 1008.1mm(L)X406.4(W)x 508mm(H) | 1160mm (L)X406.4 (W)x508mm(H) |

| Bareshaft Unit weight | 150kg | 170kg | 200Kg | 250kg | 385kg | 530 | 585 | 640 | 720kg | 800kg |